Or more accurately, when 28 beams become one...

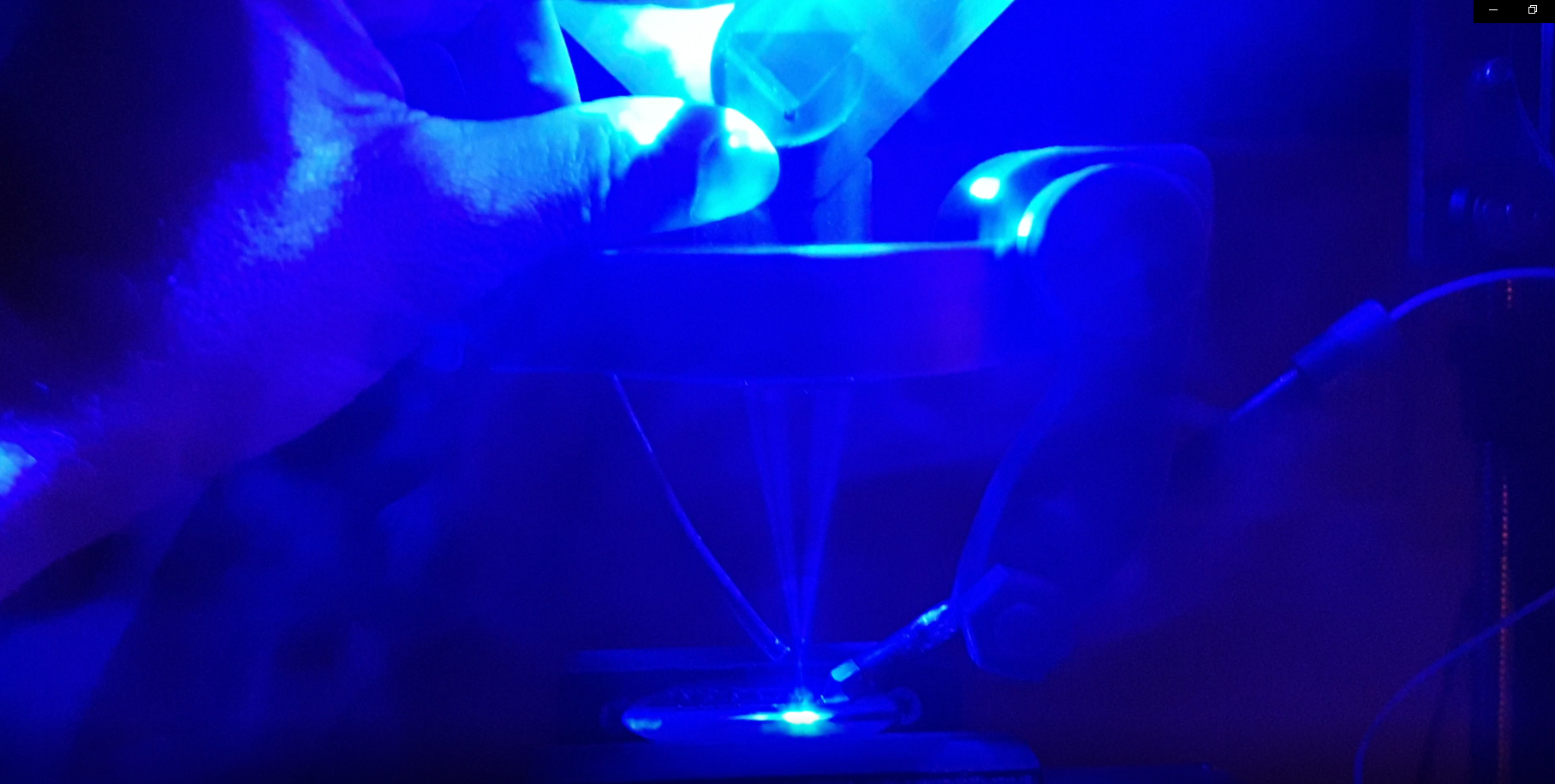

What's illustrated above is the concept for how I intend to split the beams so that wire may be fed central to the weld pool. Adjusting the prism's height allows the breadth of the two beams to be set. Admittedly, it is more efficient to knife edge the lasers and not rely on a prism but due to the lens being relatively small, and the size of each laser mount, this isn't possible at the moment. I have ordered some larger lenses and will pursue knife edging once they arrive.

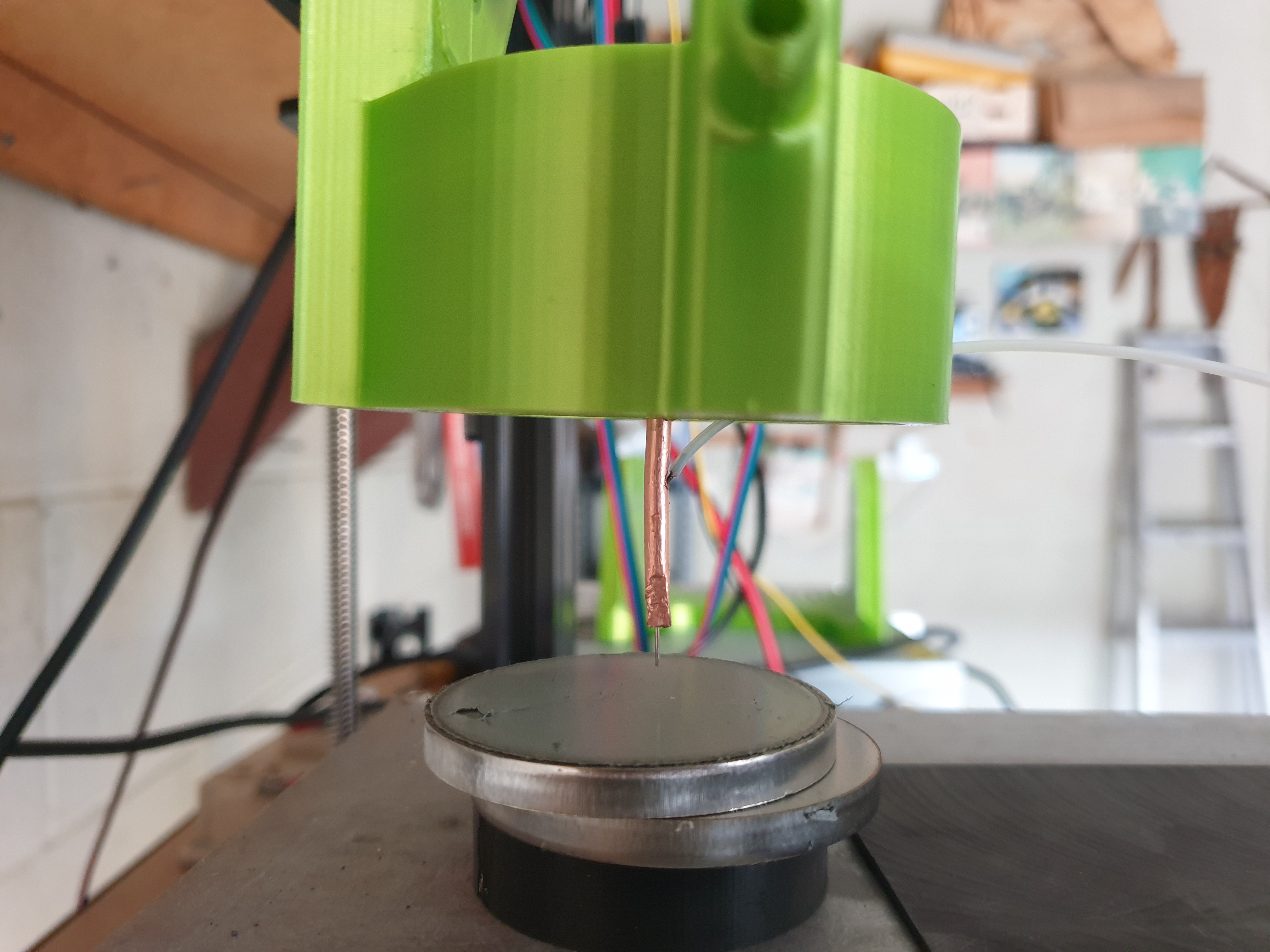

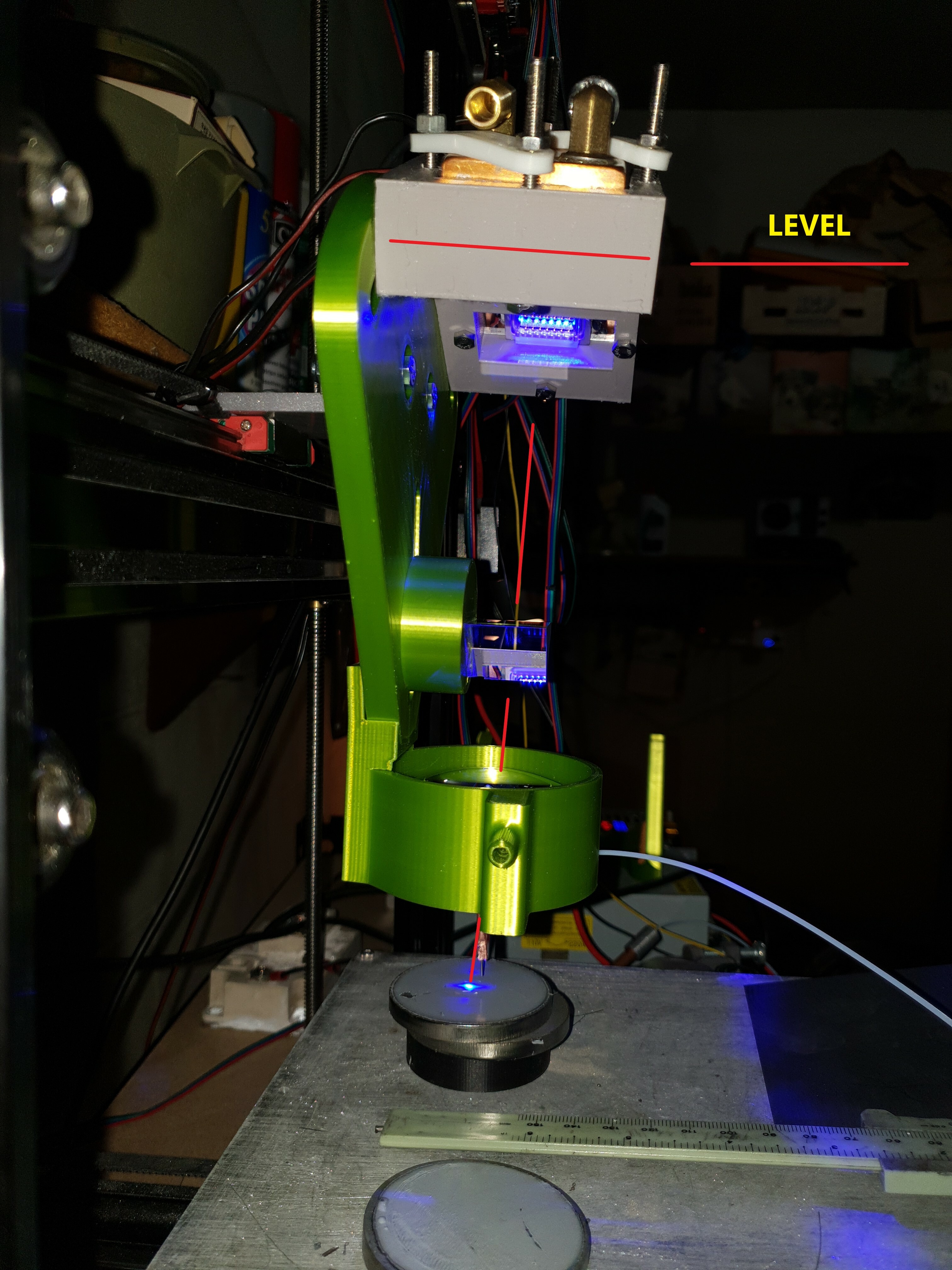

I have also been working on the head in regards to wire delivery. I had originally hoped to drill a hole through the lens to help ensure the radius of curvature of the wire wasn't too tight. However, drilling through K9 glass has proven to be a challenge so I've had to opt for something a bit more pragmatic. The syringe which delivers wire and supporting copper tubing now exists entirely beneath the lens which doesn't provide much space to work within. To try and mitigate that, the PTFE tubing which carries the wire to the syringe passes through the lens mount, helping reduce the radius of curvature and in turn lower the load on the wire feeder. I've also had to use smaller copper tubing to allow the syringe to be better supported and rely on crushing the syringe in place rather than using a modified hotend nozzle as I had done previously. Although the beams are split the space between them is quite narrow.

Despite these obstacles it seems that things are coming along quite well. The characteristics of the laser spot are what I had hoped for. As the incoming beams are aligned toward the outer edges of the lens they produce a concentric profile which is concentrated around the edge, roughly mimicking the characteristics of a professional system without the need for an elaborate lens array. Utilizing the outer edges of the lens will result in lower power density due to aberration but it's important that wire does not intersect with the laser before hitting the substrate otherwise the wire will melt and ball due to surface tension. This was one of the issues with the side entry approach as since we are working with relatively low power, wire which obstructs the laser can effectively draw away enough energy to prevent an instantaneous weld from taking place, instead forming an accumulating ball of SS316 until it is large enough to transfer enough heat to form a weld. This made the previous approach very sensitive to the angle and overlap of the wire feed. To give some context, a lot of professional machines run 1Kw+ lasers but generally cater for typical welding wire sizes (0.6mm - 1.0mm).

At the moment I am amending the laser mount design. The most recent laser head base plate is made from PLA as I am running low on PETG/ASA, which has revealed that the lasers will canter inwards when the laser mounts are tensioned in place. This is due to the slotted guides on the base plate only being around 3mm thick, the laser mounts having their mounting screws biased towards one side, and PLA's propensity for deformation when exposed to long term strain. I am printing some new mounts now with centered mounting screws and have added some capacity for fine adjustment for the sake of beam alignment.

That's all for now.

Metal Matters

16 supporters

When two beams become one

Sep 07, 2021

Enjoy this post?