I wrote the following summary in response to a member's email. I've added images and links etc here as I'm sure others will find it useful.

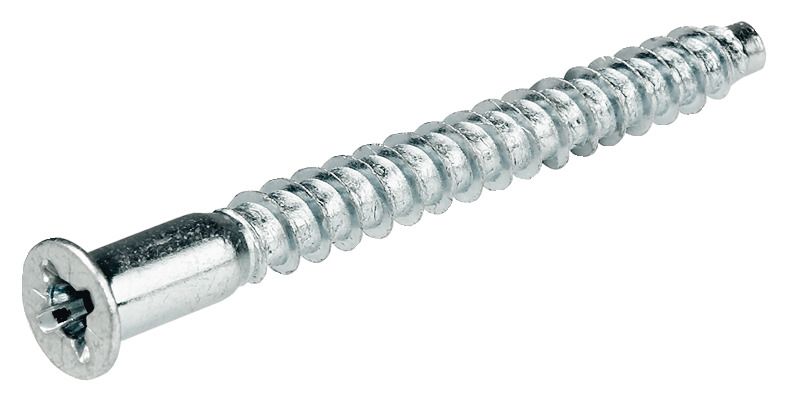

1: Kreg pocket hole screws

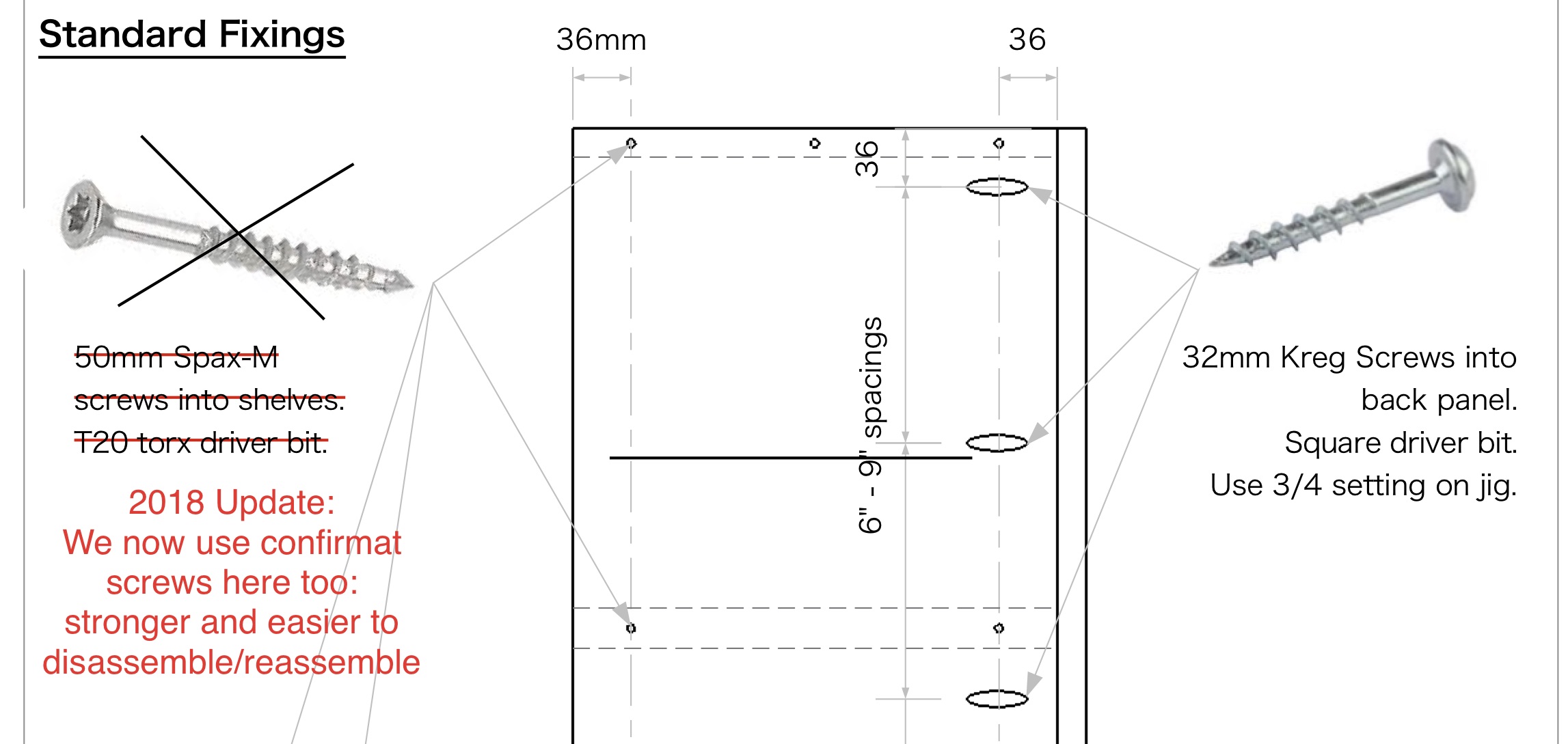

There are many variations but the most common screw, for use with 18mm thick boards, is the coarse thread, washer head, 32mm length.

Before I describe the benefits of these screws, I feel I should further clarify their description because it's very easy to order the wrong ones!! The imperial length is 1 1/4 ", and the gauge of screw is #8. You must order the coarse thread for MDF, not the fine thread, and the head style as pictured above is described by Kreg either as 'Washer Head' or 'Maxi-Lock', and while it is tempting to think of this head style as a 'pan head', in Kreg's terminology, the pan head is a different, smaller, head which is designed for use in thinner material. (See this article.)

To be sure of identifying and ordering the right ones, it's worth knowing the exact Kreg code which is 'SML-C125-' followed by the quantity of screws in the pack. eg:

SML-C125-250. (250 pack of screws)

SML-C125-500. (500 pack and so on...)

(we usually order SML-C125-5000 for best value, but I can't find a reliable Amazon link to this quantity right now!)

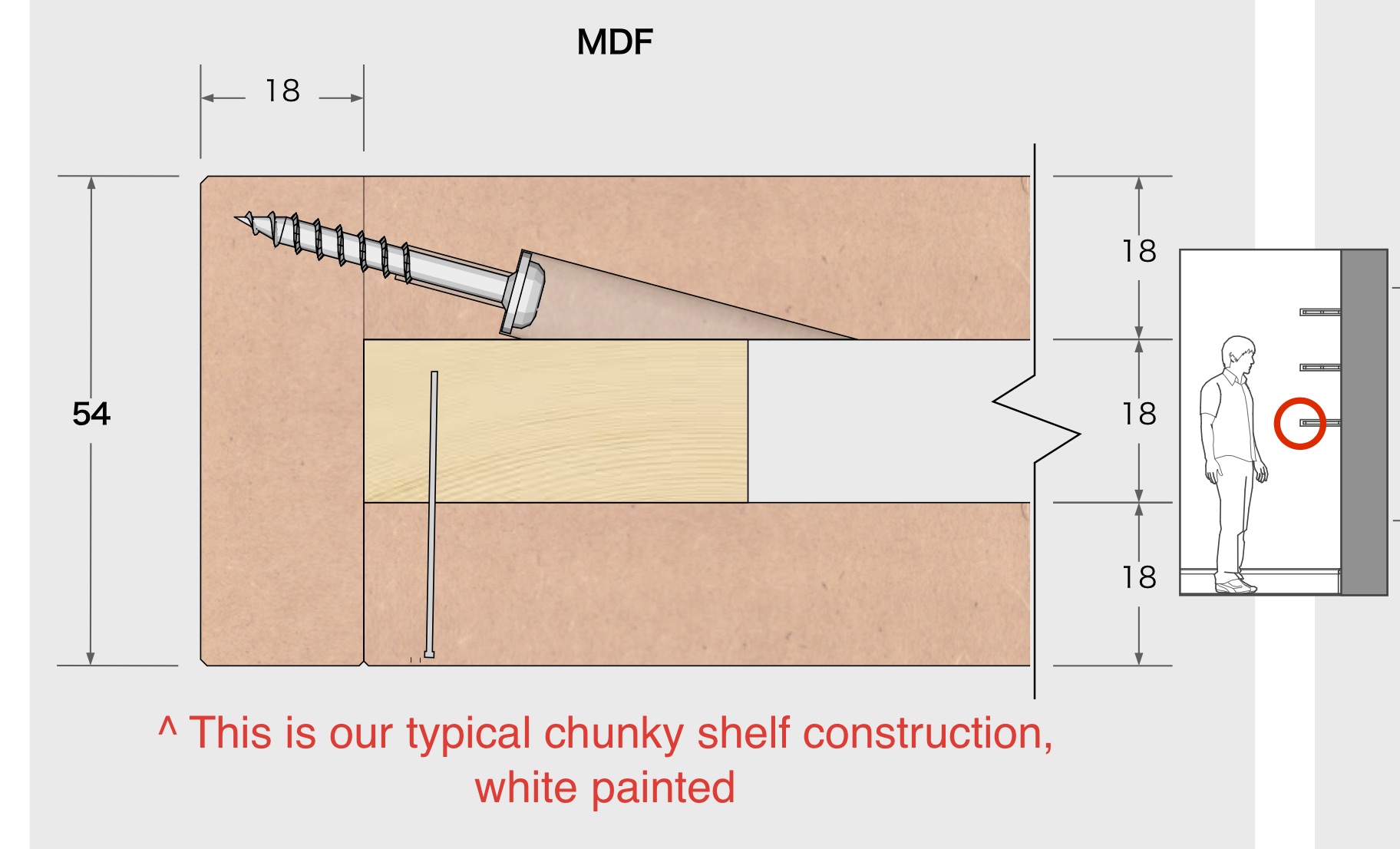

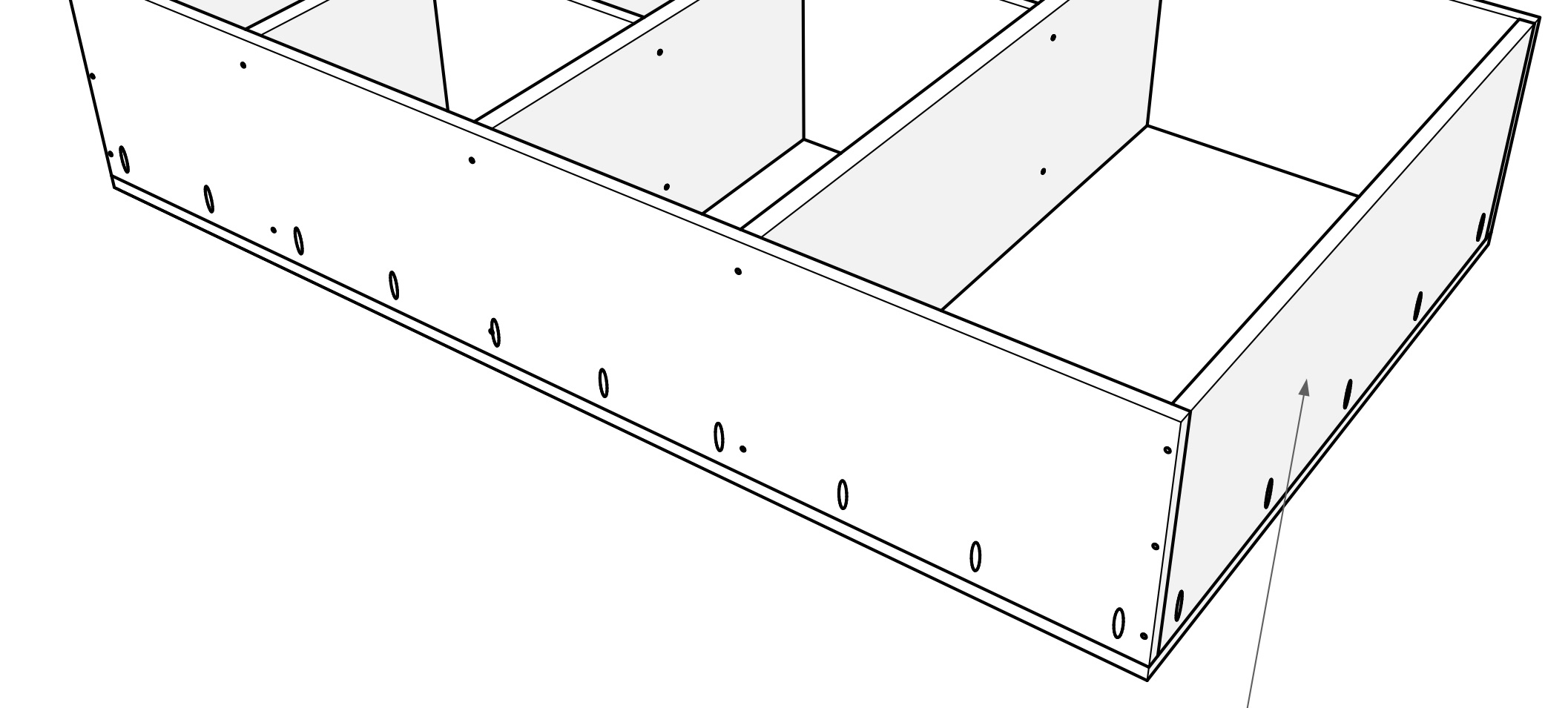

These screws in combination with a correctly drilled pocket hole are very well suited to MDF - they provide a strong joint for 90º joints in MDF because the pocket hole arrangement means the threads of the screw are gripping into the face of the board, locking into the compressed layers rather than driving between them like a wedge, which is what can happen when screwing in a more traditional way through a face and into an edge, which tends to split apart the layers of MDF.

They are only suitable for hidden locations. (I have tried the various ways of filling or capping pocket holes, for use in more exposed locations, and my summary is: don't bother!)

I am often asked why we use them for fixing sides, tops and bottom panels into back panels for most of our carcases. It's because it makes it easier for one man to assemble a unit in the workshop on the bench - you don't have to turn it over, or hop up onto the bench to get above it and screw the back panel down! And you keep the front edges visible so you can be sure everything's lined up where it should be, and gravity isn't working against you when you're fixing parts that are set back from the front face.

Drilling the pocket holes is another step in the manufacturing process but it's quite quick when we're cutting and processing MDF boards ourselves.

(With melamine which we buy fully cut and edged from Lawcris for wardrobes we usually don't use pocket holes because the delivery of boards is usually timed to go straight in the van then to the job site and we crack on there assembling on the floor - it seems less efficient to separate and handle big boards in and out of the workshop for the sake of using the pocket hole method in this instance).

It does take a bit of practice to gain the skill and judgement to make pocket hole joints finish tight and flush. But you can learn to set the parts slightly offset, then hold them tight together while driving the screw in, so they pull in to flush with the slight sideways movement. There are various pocket hole clamps you can use but they are no substitute for the speed that comes with skill and experience.

(I have not really covered the use of pocket hole screws for butt joints in frames as we rarely do this, and wouldn't really advise it in MDF, but it you did do this then I would advise the use of a bench clamp to hold the parts tight to the bench when joining to ensure a flush joint.)

To dig deeper into understanding different Kreg screw types see here.

If you are just getting started, a good value starter drilling jig is here.

Or a top end manual kreg drilling jig is this one.

We have recently stepped up to the Kreg Foreman drilling machine.

I don't recommend the Axminster UJK torx drive pocket hole screws, in my experience they snap easily, plus they are fully threaded which makes them less suited to pulling tight as easily as the Kreg originals.

It's worth noting that Toolstation have recently started selling Trend branded pocket hole screws, which look to be the same as the Kregs.

2: Spax-M MDF screws

4.0 x 50mm, 200 pack available from Ironmongerydirect.

I am not giving you an Amazon link for these because they are much cheaper at ironmongery direct.

Interestingly, Toolstation have recently started selling these too, but they are currently more expensive than Ironmongery Direct. I've just found them at Wickes too! And others now...

These are NOT the same screws as the standard self tapping Spax wood screws. They are specifically designed for MDF, with a 'spear point' tip that has a very impressive ability to self tap into MDF without splitting the edge grain. For a long time Ironmongerydirect was the only place I could find them at anything close to a reasonable price.

I used them a lot for a while, when I was fixated on the idea that a self-tapping screw was a time saver vs pre-drilling. Slowly it dawned on me that because of how long it takes pressing the screw on and spinning it until it really starts to grab and pull in, it was just as quick to pre-drill if you keep one drill set up with a small drill bit, and a separate driver for screwing.

We transitioned to using confirmat screws more often. Another factor was that, while I was partial to the torx head for a while, it was annoying to have 3 different driver bits to change between (square drive/roberts no. 2 for Kreg ; Torx for Spax ; pozi 2 for Confirmat). (As a further tangent; it was nice when we could get Kreg screws with a 'pozi square' head but I can't seem to get hold of them anymore.)

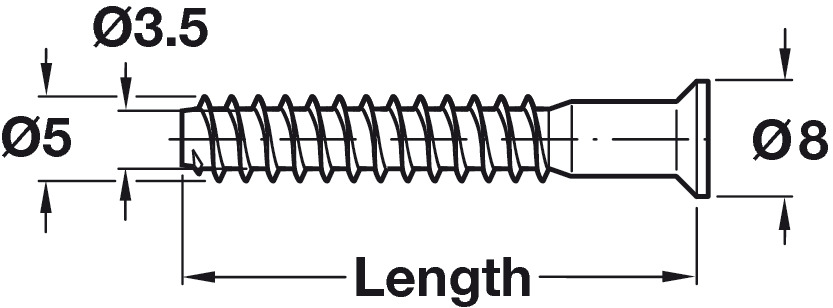

3: Confirmat screws

Size 2, 50mm length.

Hafele code: 264.37.196. (There are a few variations so that is a useful link for the correct one with a pozi-2 head)

We actually buy them from Hart Wholesale, where we get most of our hardware.

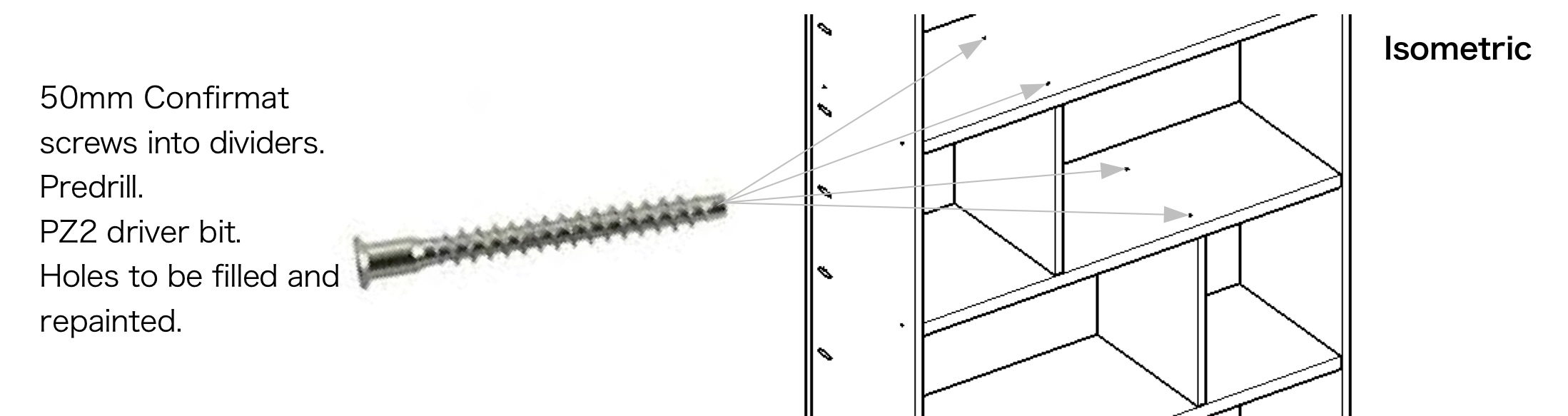

If you saw my latest downloadable blueprints document, (a link at the end of a recent post on buymeacoffee, and actually an old document), you may have seen that even when I was recommending Spax screws for fixing through the side panels into the shelf edges, I specified confirmat screws for fixing dividers.

This was at a time when we still hand-painted (Leyland eggshell with mini foam rollers), and I reckoned it was quicker and easier to screw into dividers, fill the holes and overpaint, than to use hidden fixings such as dominoes or biscuits which needed more careful setup and clamping. (That's debatable.) But having taken that position, the reason I didn't want to use self tapping Spax-M screws was because the entry hole when you recess the head inevitably raises a rim of MDF. When you haven't pre-drilled the material away first, it is being pushed out of the way by the action of the screw. This inevitably raises a slightly bulging rim. As soon as MDF has been messed with in this way it is impossible to sand/fill to flush because the fibres have lost their densely packed consistency and want to forever fluff up.

The benefit of the confirmat screws, which can only be used with the dedicated stepped drill bit, is that you get an especially clean-cut entry hole which the little rim of the head seats perfectly into without raising a fluffy bulge. This lends itself much better to a neat fill and overpaint. Alternatively you can make a tidy feature of the hole with white plastic caps made specially for confirmat screws - another advantage of the confirmat screw is it has a deep central hole through the middle of the pozi head which receives a type of plastic cap with a stalk that grips well into the hole - much better than those pozi plastic caps that always fall out!

Anyway, when we moved to spray painting, our standards went up and it was no longer acceptable to fill and overpaint. Actually we decided it was more time consuming, and you could never really make the fill seamless anyway, so we did go over to domino jointing dividers into shelves for a real hidden fixing. (Lamello would be nice but we haven't stretched to that yet).

We also standardised the confirmat screws for general use - screwing through sides into shelf edges etc - because I reckoned the predrilling was not much slower than waiting for the Spax screws to catch, but also I like the thicker shaft of the confirmats that makes them like a dowel combined with a screw, and their fairly coarse thread combined with this thicker shank means they grab very well. Because of the large diameter predriling they are not prone to splitting MDF. They work well in chipboard too.

We tried the chunkier size 3 for a while but preferred to stick with the size 2 (4/5/8mm stepped drill bit), even thought the pozi 3 head in those chunkier screws had the fortunate quirk of receiving the square drive kreg bit quite neatly!

One downside of the confirmat screws is the drillbit is ridiculously expensive. And being long it is very easy to break if you knock your drill over. You can get a cheaper Trend Snappy version or chinese versions on ebay but they are no good, not sharp enough and break easier in use, because the stepping is created by a central standard drill surround by a hollow stepped cutter that is just too easily broken.

OK, that's enough information for now I think, I hope it was helpful - let me know. If you use the links above to purchase, the Amazon ones will get me a tiny affiliate commission.